About Us

History

Ormandy Rycroft are a world leader of offsite and heat exchange solutions for all commercial and industrial sectors. Based in Bradford, we were established in 1896 and are a division of Maloney Metalcraft Ltd. Our Ormandy Newade division is a forerunner in the stainless-steel fabrication industry and are highly accomplished in the design, fabrication, welding and polishing of stainless-steel equipment.

Quality & Scope

All equipment is designed and assembled in a factory-controlled environment, where fast, efficient construction, minimises onsite labour and enhances project control. Our bespoke packaged solutions have been built upon an exceptional pedigree and manufacturing resource, alongside highly skilled and experienced Fabricators, Welders, Designers and Project Management.

Every product is bespoke and tailored specifically for your application at our state-of-the-art manufacturing facility. Our vast range of skills include bespoke design and specification, alongside manufacturing excellence with an emphasis on energy efficiency. We ensure every vessel is FAT or Hydro tested prior to leaving our factory, enabling it to be ready for commissioning and installation once on site.

Staff Expertise

Our staff have the expertise and experience to find solutions for the most complex of projects, delivering results to meet all criteria, with emphasis on energy efficiency and ensuring the vessel is fit for purpose for both immediate and long-term future demand.

Specialist manufacturing capabilities include calorifiers, copper lined vessels, plate heat exchangers and buffer units, solid copper vessels, stainless steel cylinders, packaged skids and consumer heating units, all tailored to your unique heating requirements. Whether its advice on design, specifications or manufacture, we are here to help. Just pick up the phone. Nothing is too much trouble.

Bespoke Design

Our range of solutions are renowned for quality in Building Services, Mechanical and Engineering and Offshore Industries. Unique and tailored designs enable the vessels to be built to suit spacial restrictions, with connection sizes, locations and quantities to suit the customers’ specific requirements. Bespoke vessels avoid storing more water than necessary, reducing thermal losses and enabling them to be built to specific working pressures. This results in lighter and less expensive vessels.

WORLD CLASS FACILITIES

Our Bradford facility is 5,574 square metres with 3 equal Bays and incorporates 4 cranes rated at 10 tonnes each and 2 cranes rated at 5 tonnes each. The maximum lift capacity is 20 Tonnes and maximum equipment size is limited only by crane capacity, loading bay exit size and transport restrictions.

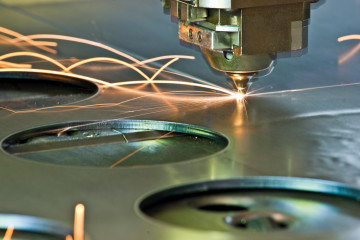

Manufacturing Activities include Shearing, Bending, Spinning, Drilling, Pipework Fitting, Rolling, Lagging, Welding, Assembly/Testing, Painting, Commissioning, Control Panel Building and Cabling/Wiring.

Joining Processes Used are as follows: Submerged Arc welding | Shielded Metal Arc (SMAW or MMA) | Gas Tungsten Arc (GTAW or TIG) | Gas Metal Arc (GMAW or MIG) | Brazing | Thermal joining plastic pipework | Solvent joining plastic pipework

Our maximum pressures are 75 Barg Design to date, although higher designs are only limited by type of equipment.

Health & Safety

We ensure Health and Safety is our top priority with optimum in-house control and vigilance. Click the link for more details.

Accreditations & Company Policy

Fully accredited to European and UK Standards, vessels are manufactured to the highest quality. For more information and to download our certificates, click the link.

Sustainability & Energy Efficiency

Whether it’s how we operate or how we design and manufacture our products, sustainability is at the core of what we do. Click the link for more details.

World Class Manufacturing Facilities & Expertise

ISO9001:2015 & UKCA/PED

EN15614-1, EN9606-1 & ASME IX

ISO14001:2015

One of only a few companies in the UK with the ability to manufacture Copper & Copper Lined Vessels