Ormandy Supply CHW & LTHW for Prestigious London Development

21 Moorfields is a large commercial development on a 1.9 hectare site in London which will provide office space. The client’s decision to work with an offsite solution was driven by their desire to ensure consistency across the project and have the HIUs available, inspected and ready for site installation in accordance with the projects critical build path.

21 Moorfields is a large commercial development on a 1.9 hectare site in London which will provide office space. Sir Robert McAlpine, the main contractor appointed Gratte Brothers Ltd as the M&E contractor for this prestigious project

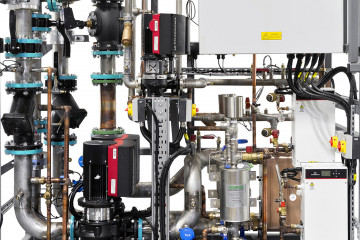

Ormandy designed & produced the Thermal Interface Units (TIU) offsite to provide the CHW and LTHW services for the 564,000 sq. ft building, including the canteen, reception and meeting areas as well as the offices.

Due to high costs associated with multiple design, it was key to ensure consistency across multiple units for a cost-effective solution.

The solution

Design Considerations to consider

- The building height & difference in static pressure across Plate Heat Exchangers.

- Spatial/weight constraints and movement on site.

- The required CHW/LTHW load and load variation across the north/south facing aspect of the building as the south required larger cooling and lower heating loads due to solar gains.

- Ensuring heat and secondary pressure losses weren’t overestimated, leading to oversized and underperforming equipment.

- Integrating package controls with the BMS system.

- Accessibility for service and maintenance.

Due to special constraints and high primary static pressure, Brazed Plate Heat Exchangers were chosen as they are a lot more rigid and compact than a traditional PHE. The compact unit also resulting in less isolation valves, as the volume within the HIU was relatively small.

Ormandy Rycroft were engaged in the project from an early stage, which ensured that the building/riser cupboards were designed around a consistent size to reduce the variation required in the frame types.

Sensors and controls were free issued by the BMS contractor for full compatibility with the system and enabled the HIU to be commissioned by them. The selected pumps were not required to be ‘smart’ as they could be fully controlled via the BMS.

Design for Consistency

The first stage of this process was to rationalise equipment across all units, to avoid small decimal point changes affecting equipment selection. Although this may mean slightly oversized piping in some cases, the cost savings by keeping the design consistent far outweighed the additional material costs. As an example, the CHW loads varied from

69-180kW across all units, this only required two different pipe sizes (65 and 100mm) greatly reducing the number of reiterations.

Variances in load (and also future redundancy) can then be dealt with by changing the BHE type to suit, which is designed into the unit and can be easily carried out on site if required. This helps to keep the overall size of the frame down.

Connections were placed on the top of the unit for ease of install and to accommodate changes in the locations of riser pipework, with pipe sizing key due to complex pipework arrangements.

Movement on site & Access

Each unit fitted onto a standard trolley for easy on-site transportation. All access for maintenance and servicing is from the front of the unit. The control panel swings forwards, allowing better access without sacrificing additional space within the frame.

TIU (Thermal Interface Units)