The Shard - Ormandy reaches New Heights

Standing at almost 310 metres high, the Shard is a spectacular glass and steel vertical city, incorporating retail, offices, hotel, apartments, restaurants and a public viewing gallery.

Ormandy were approached by MACE MEP and asked to look at the heating, cooling and hot water systems for the 95 storeys of the building.

The M&E philosophy for the Shard was modelled around offsite manufacture from its initial conception. The client wanted to simplify the engineering sequence, improve quality control, reduce the safety risks on the project programme and minimise onsite mechanical and engineering interfaces. This clear strategy was to maximise the amount of work that could be manufactured away from site.

Strategic project documents were reviewed, challenged, debated, optimised and agreed throughout all the stages of the development.

The solution

Ormandy appointed a dedicated bid team made up of specialists within their field of expertise and all communications were open and honest to encourage trust in the working relationship with the client. Drawings were integrated into the M&E model and Off-site supply was discussed at all site project team meetings. As the project developed, any lessons learnt or innovative ideas along the way were discussed and approved.

Equipment was scheduled and agreed for completion one month before delivery with any sign off and snagging carried out at Ormandy.

Design Considerations to consider

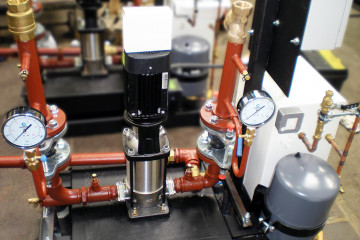

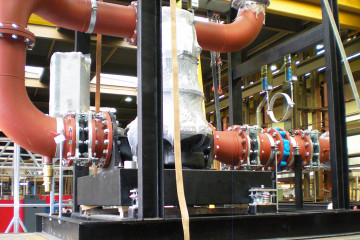

The scope of supply included Packaged Pump Assemblies, Packaged Heat Exchangers, Packaged DHW Calorifiers and Heat Interface Packages and involved working closely with the client in order to minimise the footprint of the various packages.

Offsite fabrication was maximised throughout the whole project in order to maintain the highest standards of quality, consistency across the project and enhanced Health and Safety by working within the Ormandy factory environment, based in Bradford.

Benefits to the client

Offsite construction reduced the risk aspects of health and safety onsite, with many construction interfaces with other building trades such as brick layers and plaster boarders eliminated.

Manufacturing quality was vastly improved in a controlled factory environment. All trades such as controls, electrical and insulation were completed and verified offsite, ensuring that when the package arrived at site, it was a complete and finished article ready for installation and amalgamation into the project.

As the offsite elements can be taken off the critical path, the build programme was managed with a high level of certainty, with the client just needing to control the logistics and sequencing.

Packaged Pump Sets