29th Nov 2021

OUR TECHNICAL EXPERT, DAVE FULLARTON, EXPLAINS HOW TO GENERATE DOMESTIC HOT WATER WITH HEAT PUMPS

Heat pumps are a very energy efficient way of producing hot water. The majority of heat pumps currently used in the UK are air source heat pumps (ASHP). Most generate water around 60°C or less which allows them to have good C.O.P.S (coefficients of performance).

This is ideal for underfloor heating systems and pool heating, and with some additional fine-tuning in order to raise the temperature above 60°C, can also be used for domestic hot water (DHW) storage or normal radiator systems.

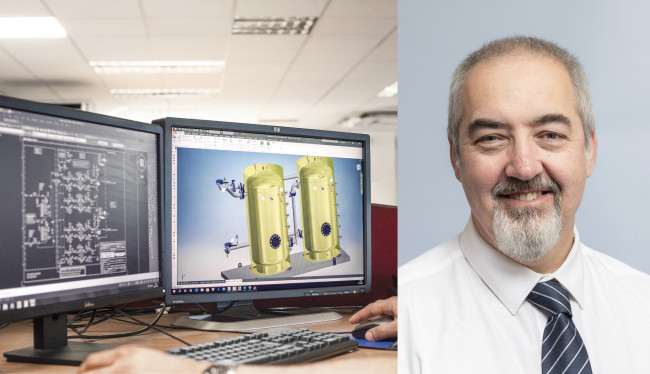

Ormandy’s technical expertise in the manufacture of hot water vessels, combined with careful design considerations from our specialist staff, have enabled us to find solutions that allow heat pumps to be used in the production of DHW.

But what information is required and why? We asked our Technical Manager, Dave Fullarton, to explain the issues and subsequently, how the Ormandy team resolve them. Dave commented:

“Many heat pumps used for the storage of domestic hot water, need to be supplemented by another means of heating in order to raise the stored water temperature to 60 - 65°C. This may be from another heat source (such as a boiler), or by the use of immersion heaters, or electric flow heaters.

Typical ASHP units, have a low temperature difference, meaning that the flow rates are quite large, resulting in the need for larger exchangers, pumps and control valves.

They also tend to be relatively low kW ratings, so recovery time can be longer than normally expected. This means consideration has to be made to ensure enough hot water is stored to suit the demands, whilst also ensuring the vessel can recover quickly enough.

Supplemental heating, if provided by immersion heaters or flow heaters, can sometimes demand high electrical loads and increase capital cost due to the need of electrical control systems.

Low supply temperature and low temperature difference means heat pump units often aren't suitable for use with traditional coils, as the coils required are often too large to fit into the vessels or leave no room for the supplemental heating sources.

Furthermore, many heat pumps will require a primary store to allow them to run defrost cycles, so space for this may also need to be considered.

Although there are heat pumps available that produce higher primary temperatures that allow domestic hot water to be produced without the need for supplemental heating, they require quite a low return temperature, which brings its own problems. Whilst the high outlet temperatures are helpful, the low return temperature can only be achieved when there is cold water available. Again, these types of heat pumps cannot be used with traditional coils.

However, with the right information and design considerations, all these issues can be easily overcome, producing a viable solution that is still cost effective, energy efficient and fit for purpose.

We asked David, what kind of information he would require. Dave replied:

“Ormandy will need to know what heat sources are available, the kW ratings and the temperature profiles they are capable of producing. Does the fluid in the heat pump circuit contain glycol (and if so what concentration), and the capacity of the vessels (if already decided), or details of the demand so a capacity can be proposed?”

So whatever your heating and hot water requirements, Dave and the rest of our team are on hand to advise and ensure that the design of your heating system is tailored to your specific requirements,

by the professionals who know how!