Buffer & Thermal Storage Vessels

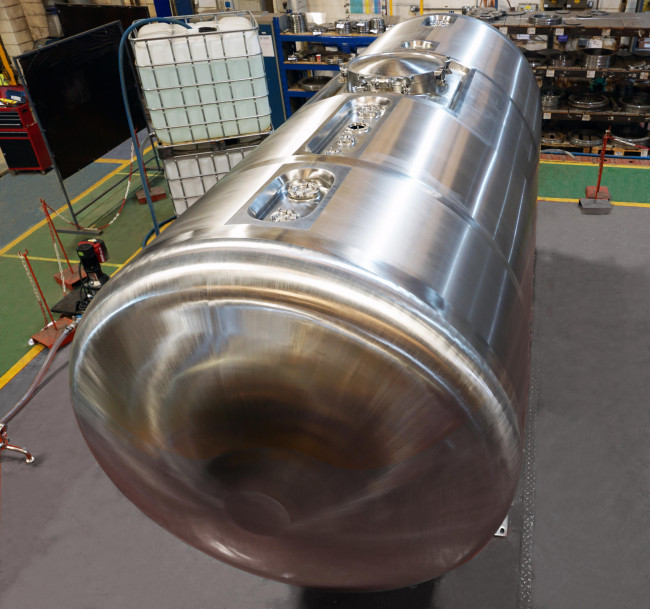

For Process applications, including Food, Pharmaceutical, Marine or Offshore there may be stringent specifications applicable. These include material traceability, third party design appraisals and inspections, along with high level manufacturing pressure vessel codes.

Ormandy Newade can also design and manufacture equipment specifically for within food process areas, clean locations, external arduous locations and extreme marine environments.

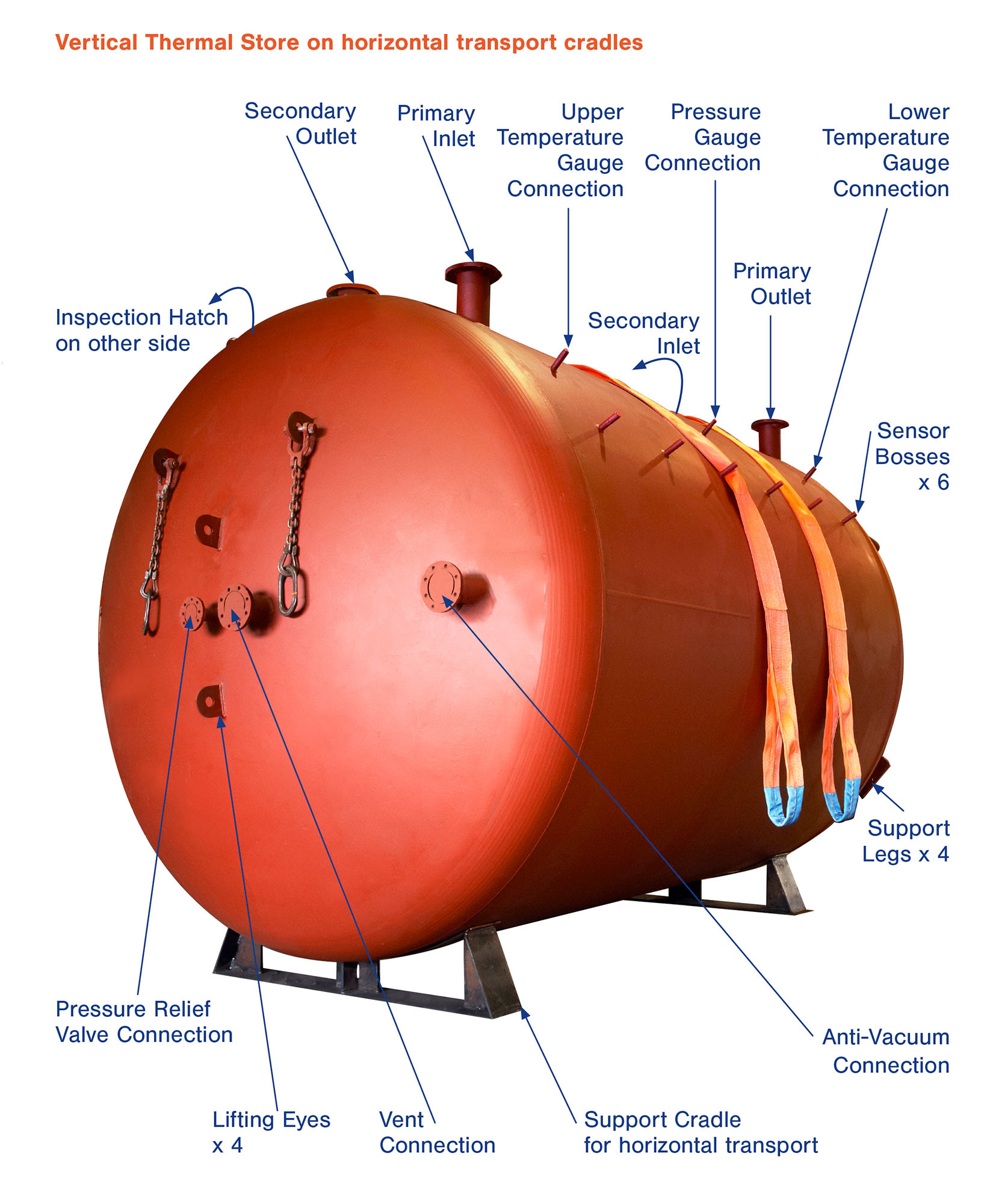

Found in a variety of systems, a buffer or thermal storage vessel provides additional storage capacity. With a greater demand for renewable energy systems, they offer both sustainability and substantial savings.

Coupled with instantaneous water heaters, vessels are connected in parallel with a pump circulation to ensure a flow between the vessel and the water heater.

Benefits

- Additional capacity when peak demands exceeds hot water generation.

- Capacity up to 50,000 litres and test pressures of 30 barg, although larger capacities and higher pressures available on request.

- Charged during low or no demand.

- Low grade heat or smaller energy sources can be utilised.

- Vented and unvented systems.

- Supplied horizontally or vertically.

- Increased energy efficiency of the heating system.

- Rapid pay back as heating costs significantly reduced.

- Can be connected and combined with several power sources.

- Insulation for chilled water applications.

- Vessels manufactured in carbon steel, stainless steel or copper.

Product enquiry

Thanks for your interest in Buffer & Thermal Storage Vessels. Please fill in the following information so that we can get back to you as soon as possible.