Process Plate Heat Exchangers - Gasketed, Brazed & Packaged

For Process applications, including Food, Pharmaceutical, Marine or Offshore there may be stringent specifications applicable. These include material traceability, third party design appraisals and inspections, along with high level manufacturing pressure vessel codes.

Ormandy Newade can also design and manufacture equipment specifically for within food process areas, clean locations, external arduous locations and extreme marine environments.

A comprehensive range of WRAS approved gasketed and brazed units for all heating and cooling applications and selected to optimise performance based on rating, temperature and pressure drop criteria.

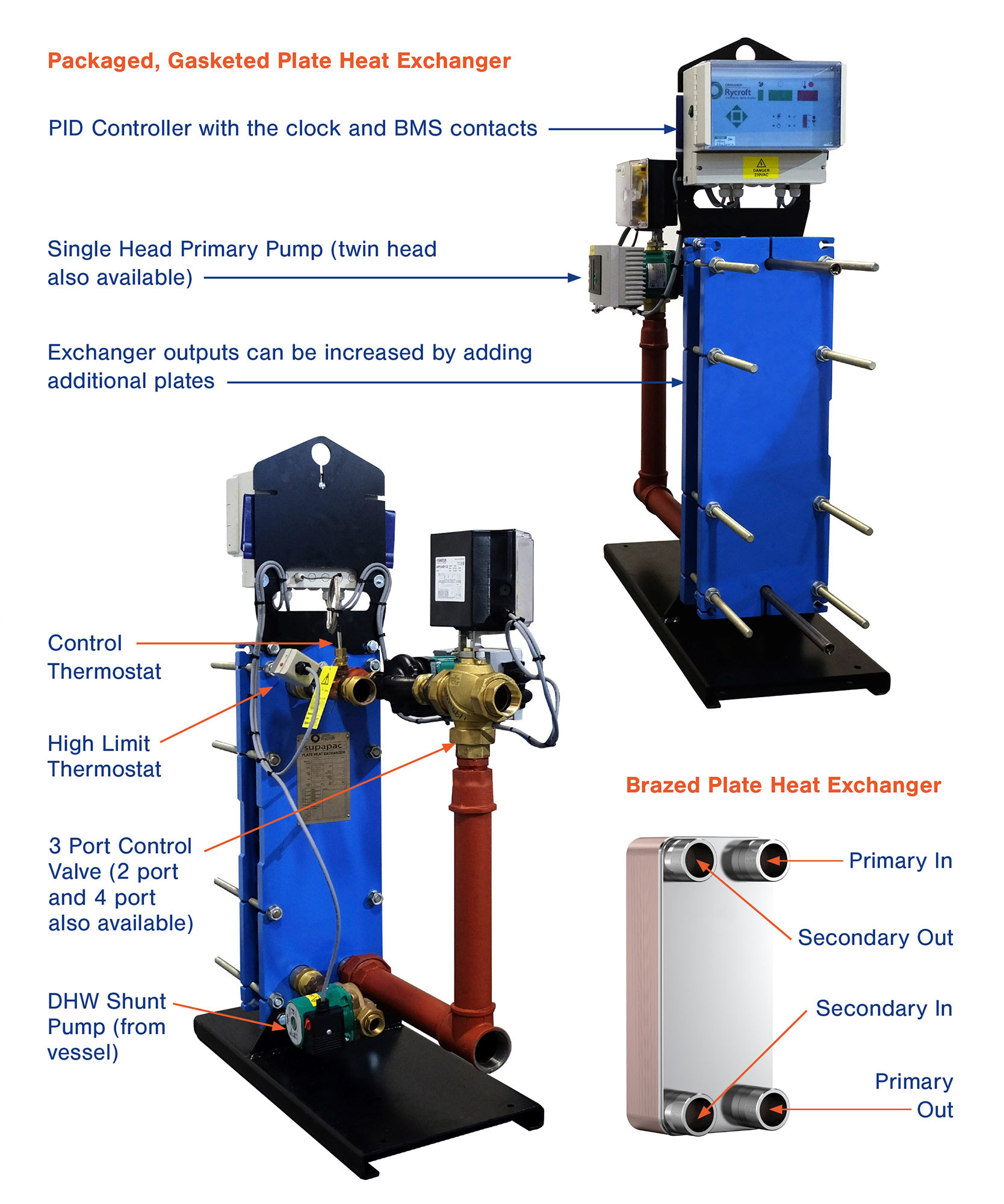

Our Packaged, Gasketed Breeze Range include:

HT-Breeze is an instantaneous water heater offering an economic solution for the provision of hot water with a quick heat up, rapid response and negligible standing losses.

Vari-E-Breeze Plate Heat Exchanger combines variable speed technology of the latest pumps for closer control of output, greater speed of response and enhanced energy efficiency and lower running costs.

Industrial Breeze Plate Heat Exchangers are generally used in harsher environments, where higher pump duties require electric motors with larger running currents.

Benefits

- Runs on demand with greater speed of response and lower running costs.

- Outputs from 0.25L/sec up to 5L/sec. Larger units available.

- Choice of materials – stainless steel 316L, 304L & titanium.

- High heat transfer coefficients ensure the design surface area is kept to a minimum.

- Exchanger outputs can be increased by additional plates.

- Exchangers achieve high cross over temperature profiles.

- Enhanced energy efficiency and closer control of output.

- Low standing losses compared with other exchanger types.

- Single or twin head variable speed pump with self-protection built into the pumps for longer pump life.

- Night set-back & anti-legionella pasteurisation feature.

- Remote operating temperature display and adjustment of set points.

- Compact design with a small footprint and ease of maintenance.

- Vented and Unvented applications with 2,3 or 4 port valve operation and full BMS compatibility.

Product enquiry

Thanks for your interest in Process Plate Heat Exchangers - Gasketed, Brazed & Packaged. Please fill in the following information so that we can get back to you as soon as possible.